Now that we’ve created the ultimate digester,

Now that we’ve created the ultimate digester,

let’s look at creating biomethane out of biogas.

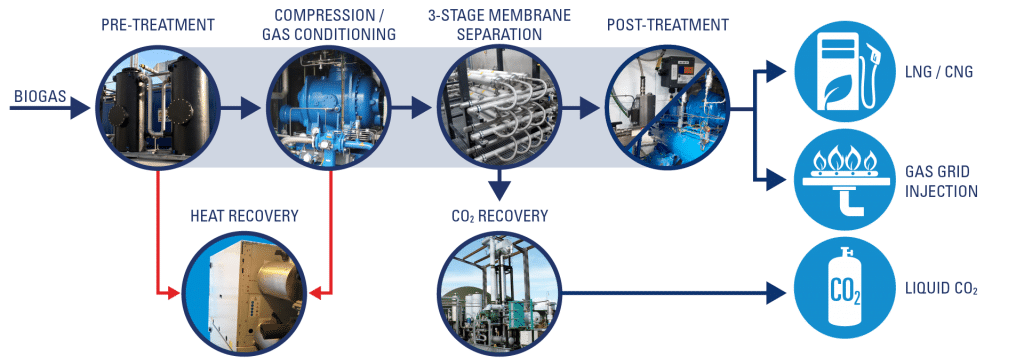

Bright Biomethane system uses Triple Pass Membrane Technology to separate methane from biogas.

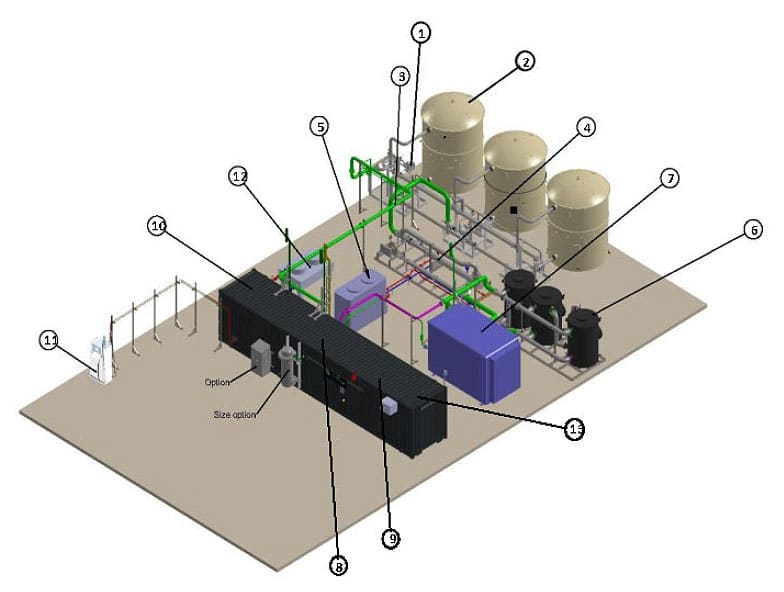

1. Blower to push biogas through the iron sponges

2. Iron sponges

3. Blower for biogas to the flare (after iron sponges)

4. Biogas chiller skid

5. Chiller

6. Activated carbon filters

7. Biogas compressor

8. Membranes

9. Chromatograph – controls biomethane to pipeline

10. Biomethane booster compressor

11. RNG trailer docking station

12. Compressor cooler

13. Control room

Technology

In the membrane unit, the gas is separated by means of an imposed pressure difference over the membrane, Two gas streams will be obtained from the plant; a product gas, with a high methane value, and a CO2-rich gas. As a result of highly selective membranes and the recuperation of methane, the highest possible methane yield can be achieved. Depending on the application the gas can be upgraded to the preferred methane value.

Application

One of the applications is to inject the obtained gas into a national gas grid. It can also be used as transportation fuel (CNG/LNG) for vehicles, In both applications the patented 3 stage separation process ensures that the gas meets the requirements for a specific application. The residual heat and the CO2 can also be utilized. A special heat recovery system can be installed to produce high temperature water and CO2 may be recovered and liquefied to provide an additional value stream.

An entire 100-600 scfm direct inject system sets on a 60’ x 60’ pad.

(+ truck parking if virtual pipeline is used)

– For higher volume systems, a larger pad is needed.

From being one of the industry’s

leading CHP providers …

to being a full digester

EPC provider …

to partnering with a leading biogas upgrading technology providers.